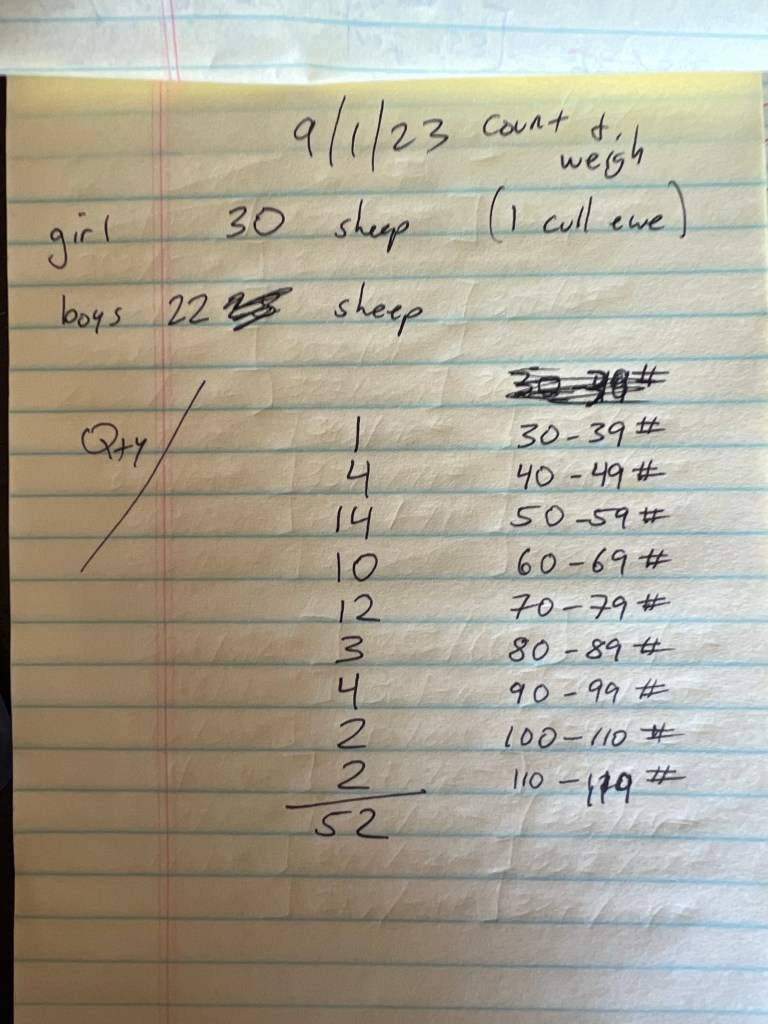

Slowly but surely we continue to get little things done but nothing holds back Mother Nature. Yesterday one of the ewes gave birth to our first lambs this birthing cycle, a set of twins! Of course the sheep were on the back hillside about halfway down to the schoolhouse. Annmarie happened to spot them from the driveway when she was returning home. I walked out and tried to catch both lambs but could only get a hold of the little brown one. Both lambs were still wet and the mother had not passed a placenta yet. The little black one ran with mom all the way back to the barn. Annmarie caught it as it was trying to get into the barn. She used the lamb lure to get the mother to run into the momma/baby area. The barn lights are amazing! You can clearly see in the needed areas but you have to plan ahead as you can only use two light strings at a time. It is a huge improvement, I should have done it two years ago when I saw the conversion on YouTube. We will keep the momma and babies separated. We have the momma/baby barn lot run locked off so the grass is about eight inches tall in that area. The ewe will be happy. In three days we will let her out with the twins and they can start to get in and out of the barn by themselves. I believe there are 38-39 ewes and not all of them are pregnant. We will count as we go. I will start the statistics after we get a few more lambs. There were no new babies this morning. I will be doing morning duties so when I wake up at 0400 I will now be going to the barn to check for babies first thing and feed and water any new mommas and let everyone out of the barn.

Mr Rainman came out midweek and got the large hay bales covered. The grass in field 4b is very tall. I may end up putting up a fence around the hay with a large removable wire gate for the front. I would need to put it far enough away from the bales that the cows and sheep could not reach through it to get the hay. The old road sign tarps are very heavy duty! We will see if they can last through the winter and wind over the next four months.

The new chicken door came and Mr Rainman installed it. The door closes just after it gets dark. It has a built in solar panel so the AA batteries will keep charged. It has a flashing red light that starts up and means the door will close in 30 minutes. I know this as I have been looking every evening to see if the door actually shuts. I am doubtful that the chickens will learn that they have 30 minutes once the red light starts flashing. It has been pretty dark and the door is still open. The door does cycle and the chickens really are that stupid. Some know to get into the coop before dark but others want to be out late and miss the curfew. Those chickens have to wait outside until the next day. My hope is with the new run door they will be protected despite their tendencies to stay out late partying. The last step will be to put in some overhead 2×4 rafters and run chicken wire over the top of the run so that the chickens are truly protected from all predators.

I got a new outlet wired in the root cellar stairs so when the new LED lights come I can install them quickly in the ceiling of the root cellar. I had left a empty wire conduit for just this purpose on the side of the box. What I failed to realize was how much harder it is to add things after the fact. I did actually have to turn off power in the box so I could get it all wired up. I also cleaned up the last of the barn wiring supplies so the barn is ready for the lambs. I have been doing a lot of little tasks. They all need to get done but I get frustrated, it feels like I am working the last 10% of a project; I am but it is still annoying.

Fall is definitely here and since the ewes cannot go on the back hillside anymore I am using them to clean up our front hillside and make the leaves in the yard disappear. The dogs do not particularly like staying in the house all day, especially the puppy. She wants to be outside digging, I filled in four huge holes in the yard yesterday. But after she learned to jump the low fence from the garden area she cannot stay outside. I don’t want to install that side fence permanently until after we manage to get the siding replaced. We are still looking for a contractor! It is very hard to find someone reliable and good.