It has been one of those weeks, The Apprentice wanted to keep working all week. The fence building did not deter her. We have two leaky frost free faucets that need to be replaced. Unfortunately, to do that they have to be dug out. This is due to the reducers that had to be added to match the 2” pipe that is original to the farm. I placed some tools on the ground to outline a space and asked her to dig. She knocked out the first hole on day 1. Her only real obstacles were the dogs kept dropping the throw balls onto her head when the hole started to get deep. I imagine she threw the ball all day for both dogs. I am sure they loved it. I saw her on her way out and told her there was another faucet in the back yard that needed dug out but it was near a tree stump and would probably not be as easy. This did not seem to deter her and The Apprentice stated she would be back the next day.

Thursday morning, she texted me around 0930, a late start for sure. I am sure that first hole was causing some physical discomfort. I had messaged her first thing to check on a sheep carcass in the orchard. My mother-in-law had called me at work stating she thought there was a dead sheep in the orchard. The Apprentice confirmed there was indeed a dead ewe, #325, in the orchard with no intestines. I told her to just leave it. She tore into the back faucet with less enthusiasm and more problems. There were tree roots everywhere and she had to keep cutting through them. I knew this was going to be a problem. She had to leave around 1330 and said there was more to dig.

When Annmarie came home she called me at work to tell me there was a dead sheep in the orchard. I had forgotten to tell her. She had spotted it because there was a Golden Eagle feasting on the carcass! I asked if she had gotten a picture of the eagle, nope. We discussed my failure to keep her informed and that the sheep had to now be brought into the barn lot. This means running them through the front yard every night and letting them back out every morning. I opted to leave the carcass in the orchard as I was going to be around the farm all weekend and wanted a crack at the coyote doing this.

Friday morning when Mr Rainman and I went out to fix the gate into the tree orchard area, he hit it with the tractor earlier in the summer. We noticed that the carcass only had the head intact and three legs. One leg was missing and one was off in the pasture about 40 feet from the carcass. It had been stripped down. We found a dig out spot under the fence. This is where the predators have been crawling under the fence to get to the sheep. It was a fresh crawl spot and the dirt was still moist. We ended up planting a wooden post in the field and mounting the electronic eyes on all four sides of the post. They are solar powered with a battery that lasts all night. So they charge all day and then light up and flash at night. It is supposed to look like light reflecting off of eyes. This is supposed to scare the predators off. We got everything mounted but did not turn them on. I went back up to the machine shed and created a snare to place over the hole. We are going to leave the carcass in the orchard for one more night to see if something returns tonight. This meant that the four vultures that showed up today got to fill their bellies all day long. They were pretty satiated. I will move the carcass tomorrow if we don’t catch anything. If we do I will try the snare a second night. Who knows what will happen.

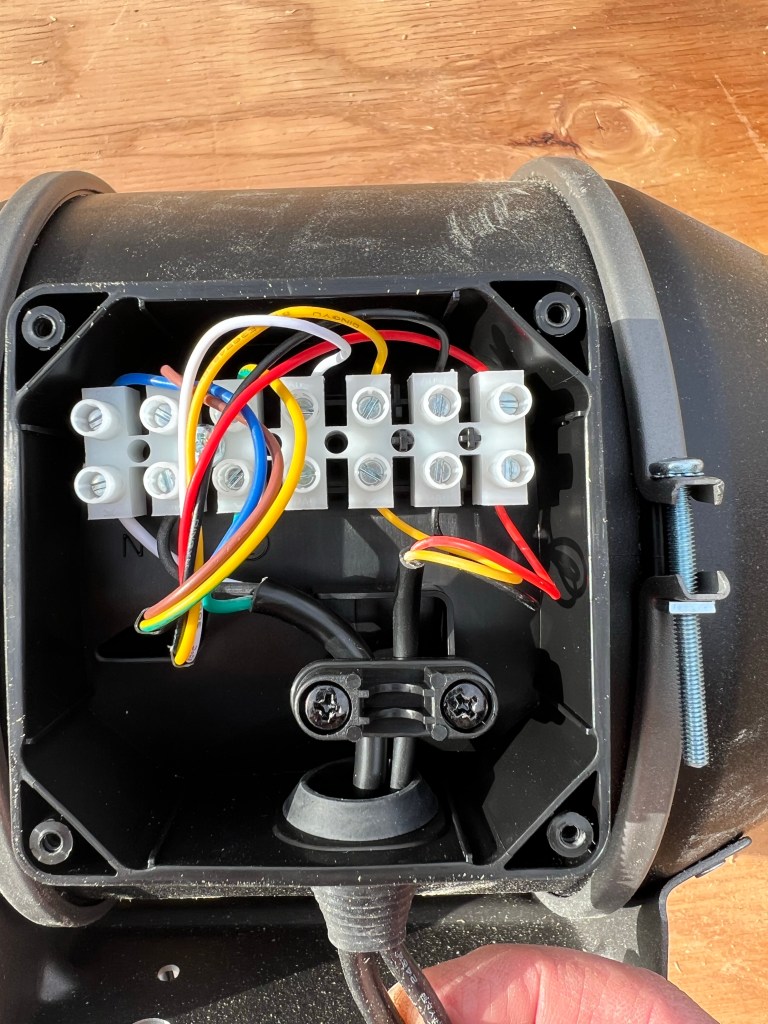

We carried a rifle all day while working on the fence and faucets and did not see a single coyote. It is so painful to have the thing on you most of the day. We finally just put it in the pickup so it was out of the way. We did get the frost free faucets changed out and they work and do not leak. The Apprentice can fill in the holes at a later date. We went up and pounded T posts in on two sides of field #1. The stupid flood buried the woven wire alongside the road in two different places. We will have to cut the wire and splice in new to sit above the dirt. Their is a large drop off so we had to pound the T-posts in by hand alongside the road.

We measured the fence line distance alongside the creek. Each roll of woven wire is 330’. So I decided that instead of trying to wire all the woven wire into one long contiguous piece of wire I would just install them in 312-320’ increments. We marked out a H brace every 312-320 feet. We can install one entire section of fence, tighten it up and then attach the new one and do it again. Their needs to be some H braces interspersed along a long fence anyways and this made perfect sense to me. We marked out all of the H braces and drilled the first holes with the 6” auger. The rain we had earlier in the week and the storm we had today made drilling into the soil very easy. We got 5/100” of rain today. I missed out on measuring the earlier rain storm due to a dead battery in our rain gauge, I fixed it on Wednesday.

I did try and call the animal auction yard today but no one answered and their voicemail was full. I will try an email this weekend. We have 55 lambs that need a new home with only five sold at this time.