This was a very productive weekend! The office took up half of the weekend, not the exciting half but definitively the productive half. I spent a couple of hours on Friday pouring over the instructions on where to attach the door hangars. They only needed to give one measurement, the distance from the top of the door to the bottom of the wheel. No where in the entire instructions, which I kept from last time, did they bother to give that distance. They gave some other random distances and spots on the door that were wrong but not the one I needed. I ended up getting a couple of clamps, cutting two small pieces of wood to the hanger and trying to get it to fit onto the track. I managed to find the correct height, then I measured the door from the floor, subtracted the gap at the bottom and the gap at the top and came up with a door build height. I rough cut the 16 foot board at 82” on one side so I could get them out of the old house alone. It took two of us to thread those 16’ boards into the cramped space. I stacked the boards in bunches of five then cut off both ends at the same time so the boards all matched. Mr Professional came out and we set up a workspace out in the yard. I was initially opposed but after assembling two doors next to the saw in the sunshine, it was nice.

I had come up with the design of using the 2” wood for the X but I had a star pattern drawn out on a piece of cardboard and before I could stop him Mr Professional had ignored my pattern and we went with the hollow X. The next day we tried my pattern but I realized that I would have to cut every single piece in half and I was afraid it would cut down the structural strength of the door. We made it out of tongue and groove that we also used on the walls. We glued them then used pipe clamps to squeeze them together and then screwed on the cross pieces and hung them up on the wall to dry. I think I could have perfected my X cross pattern if we had made a third door. They are not exact but you have to pay attention to notice the difference. This was done on purpose. The direction of the long X pieces on both doors was deliberate. Ideally the screws would all line up but we had to miss knots in the wood and this is not a factory thing, it’s supposed to mimic a barn door and most people don’t measure out placement for screws on a barn door. I just need to rub on the finish for both doors. It will only take an hour but today there was no time.

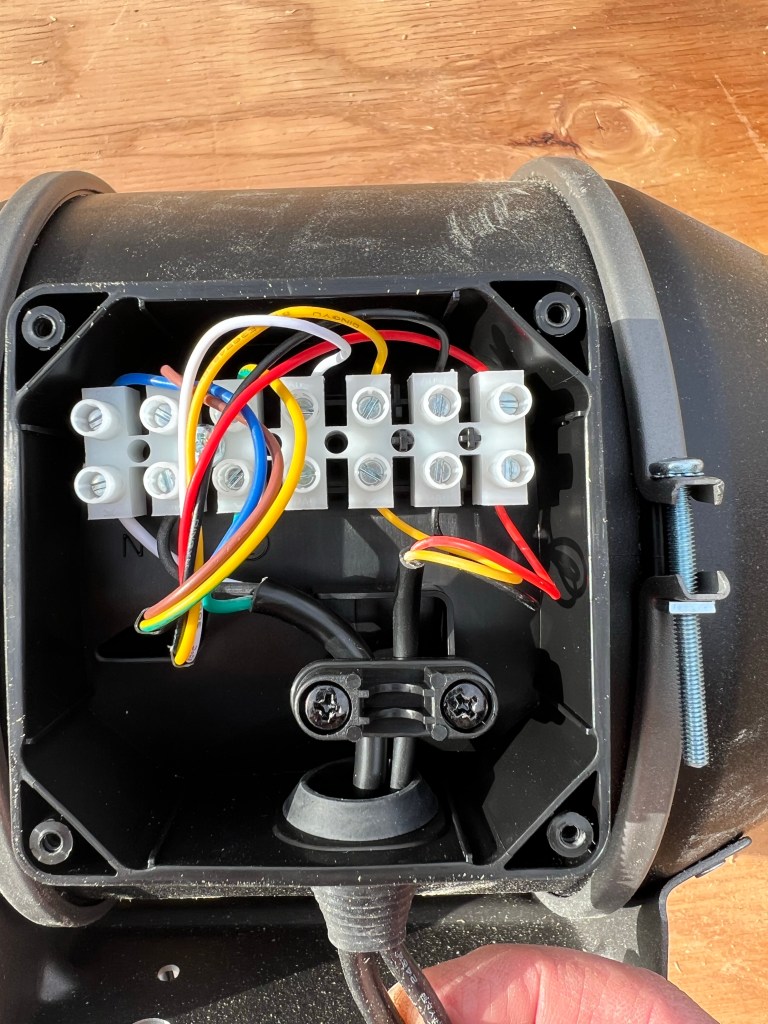

We needed to get the Glowforge laser engraver all set up. I had purchased duct work to vent it out the side of the room but I failed to account for the actual width of the laser. I ended up running to town and getting metal dryer vent solid ducting and a clamp on connector. We then just drilled a hole right out the back of the laser through the wall and mounted the actual fan outside the building. This means we had to make a shelf outside and we will have to build an enclosure around it and put on a slanted roof over it to shed water from the corner drain off the roof. To get the fan controller through the wall I unwired the controller from the fan allowing us to drill a small hole and use a piece of copper wire to pull it through. This then meant there was no power for the fan outside the house. So I had to kill the power, get into an outlet box and drill out the back of the box to outside and wire in jumper power to a new outside box. This was done and we were able to verify that the fan does work. We added a screen to the inside of the vent so that birds could not fly up the vent. I need to get a waterproof cover that allows the plug to stay plugged in.

We had purchased a sheet of cork 2×3’ long to put behind the Victrola wooden screen we removed from the front of the Victrola. It turned out pretty nice other than I mounted it on the wrong side of the desk. I hung up the office clock after I ensured it was going in the desired spot. The only thing left now is to finish the insulation in the attic, install the attic vent fan, getting freezer room floor installed and then completing the wiring in the second room. Luckily, the only thing left that the wife can see is rubbing on the oil finish on the door, a mere 1.5 hours of labor.