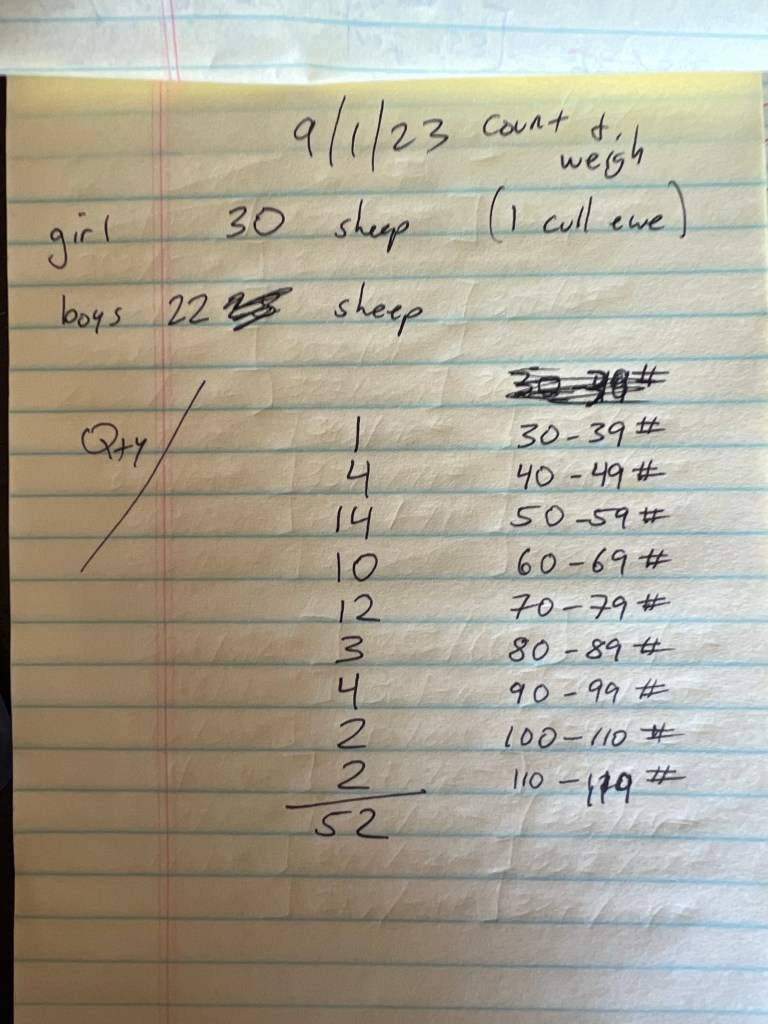

It’s been a while since I blogged. I blame it on the Pendleton Round-Up. All the locals say time stops and all projects go on hold while it occurs and the reality really does reflect the saying. I have been picking fruit non stop every few days and Annmarie has been drying it, canning it or freezing it. We managed to get the 50 lambs sold before the coyotes ate any more! A person from the west side of the state came over and got all 50, he was gone 20 minutes after arrival. We had them all ready to go. Honestly, this is the best way to sell lambs, all at once. We got a fair price $100 for all over 60# and $80 for all 40-59#.

The apprentice came out for a few hours a couple of days and weeded the hillside again and went in and cleaned up the lavender patch. The patch looks great, I just need to trim it all for the winter and we will be ready for next year. We have about five plants that have taken off on their own and need to be replanted. She is about ready to go off and learn to be a farrier at the end of the month. We will have to tear out our garden soon as the temperature has started to dip down to 45F at night. We have prunes drying in dehydrator now as soon as they are done we will dry the last of the spices before winter.

I had another project for my mother that I was able to get completed before it froze. I said I would be able to do it at the beginning of summer and managed to get it done with a lot of help from a lot of other people. My mother and sister did a great job. Now I can start working on the back bridge foundations.

The quail are everywhere! You literally cannot walk around anywhere on the farm without running into a covey or if you sit still you can hear them calling from all over. They are so used to people that as long as you are 30’ away they will just ignore you. This bodes well for a healthy population going into winter. We also have two covey of Hungarian partridges. We usually only have one on the farm. We also have a bunny rabbit living along the driveway again.

When I leave for work and the moon and stars are out I always try and take a picture with my phone. Sometimes it works out, sometimes not. I keep trying.