Month: March 2015

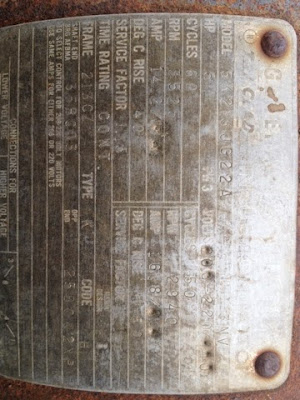

More pump surprises.

|

| Irrigation pump stats |

I went out to the pump for pictures and a transcription opportunity. The motor was three phase. Two years ago I got the pump to work, and it just kept bugging me that I could not even get a buzz out of it this time. A buzz would have made me happy. I started looking harder, and then I looked up, way up into the sky! One wire of the three had been shot in half. I need to get an electrician and boom truck out to the farm to get the line repaired. Hopefully, they can repair it and not make me replace the whole thing. Once the overhead line is repaired I will go back to worrying about the control panel.

I picked up the rest of the lumber for the kitchen cabinets today. Sarah had to help me unload 3/4 inch oak full size 4×8 feet sheets of plywood. She was not impressed and still sore from her drill weekend. There was much cajoling on my part. It was still easier with her than doing it by myself.

Irrigation pump woes.

|

| Pump control panel issues. |

Rain let it rain! We need some moisture, so our irrigation project has moved up the priority list. I went out today to get the pump working. The cover is ancient and rusted but I knew the bugs where getting inside the panel. I had no idea how many different types of insects, flying and crawling kinds were living inside. I did wonder if there was any live power inside. I couldn’t see anything so I broke off a dead thistle stem and used it to clean out the panel. I spent over 30 minutes just scraping hornets nests, spider webs and mud wasp nests out. I did use an electrical tester and found no power. Being a wise grasshopper I did not believe it. I kept my leather gloves on and used a wooden handle wire brush. When the wire brush started sparking I was not surprised. The power was right at its entry point. There is a large mechanical breaker hidden in the back of the upper fuse assembly that is operated by the outside handle. There is a small switch on the right outside of the box that is broken and will not turn. It is the run switch and will need to be replaced. The bottom solenoid assembly needs to be replaced also. I plugged the holes and bent the upper panel to prevent the bugs from crawling past. I had to put in a new wire clamp pass through on the bottom of the panel.

|

| Painted and labeled box. |

I opened up the pressure switch near the pump and had to dig out more bugs so the contacts would be able to close. I could not get the pump to work. I could not get the lower solenoid to operate at all. The dirt needs to be dug out from the channel as an added bonus. I used a wire brush on the outside of the entire panel and painted it with some dove gray vehicle primer. It was very windy but I was quite surprised at how good the spray nozzle on the can worked. It gave a narrow wide spray of paint. As someone who painted an entire car with can paint I can attest to how much better the modern nozzles are twenty years later.

My little sister, Chris, came out to visit. She wanted to pet an alpaca. I had caught one the other day for Lori, my other sister, and she had spread the word about how soft they were. I fed early so we could touch them. I snagged the little black one and held on by just grabbing its hair on the back. Chris got to pet it and then she wanted to pet a white colored one. So I wandered around and leaped toward a brown one. I grabbed its back hair near the neck and it started to fight me more than the first one. So I decided that my manly 165 pounds would subdue this creature. I threw my leg over its back and straddled this small weak creature. My toes were barely touching the ground then it started running and bucking! I just held on. I made it about 12 feet before getting thrown off. I landed on my hands and toes. Chris was laughing after she asked me if I was okay. She had her back to me and turned around in time to see me riding said mild mannered creature and subsequently getting bucked off. Note to self, do not straddle alpacas.

More brain power needed

|

| Metal scrapyard haul! |

I went to the scrapyard yesterday. I needed to pick up my dad’s wheelchair before it got altered. While there I picked up a trailer I can use with the tractor. They pointed out all the T-posts that had been saved over the winter. I had to have those! I dug through and collected 135 T posts about half need to be straightened. The rest can just be pounded into the ground. They only had a couple of small woven wire rolls for me. As an added bonus they had just got in four slightly used cow panels. I snagged those for use as round protectors for our new baby trees. Grandma Lane gave us six new one year old black walnut trees. They need to be protected from all livestock and deer. The trailer will need a front tongue support. I will take if off of an old camp trailer we have at the house. I will then be able to load it with the tractor and then hook up and pull it with the same tractor. I will now be able to move compost from the barn lot to my back rock wall, allowing me to build the wall higher. The T-posts are not necessary but I buy them every time I find them because they will be needed eventually.

|

| New wall oven. |

I picked up our new wall stove and Gannon helped me get it into the house. We tried to get it into the library while packaged. Not going to happen, we got stuck in the door way and had to cut it out of the packaging to get it in the rest of the way. I needed it out of the packaging so I could take some real time measurements. I think better with a tape measure.

I cooked a meal on the installed cooktop last night it was very nice, easy to use and had a nice even heat. This morning I went to light the central burner and it would not light. I kept trying then lit a side burner, WHOOSH! I burned all the hair off the back of my left hand. There was quite the collection of gas on top of the stove when it finally took off. Definitely, need to get a handle on how to actually light the cooktop while I still have a little hair left on my head.

Wall Oven Ponderings

|

| Oven cabinet for back wall in kitchen. |

Annmarie and I sat down the other day to decide how to go about installing the freestanding oven on the back wall in our kitchen. First, we are going to move the sideboard into the dining room. This is where it belongs as a working piece of furniture. Next, we measured the space 71 inches wide and decided it should be as tall as the other shelves I made out of old doors so 79 inches tall. Annmarie then printed out the installation instruction manual from the internet so I could get actual dimensions. I sat in a chair and drew stick drawings while she got on the computer and mocked it all up. We will have three separate cabinets. This allows for ease of mobility. As a single unit it would weigh a ton with a 155# oven installed. This also lets me install the center and get some exact measurements for each side. All three pieces will stick out from the wall 24 inches. I was going to go with 2×4 notched for 1×4 side supports with plywood across for shelving but that takes up a lot of width for six boards plus siding. I would waste almost a foot of space. This was the rough draft. It will have two doors under the stove with pull out drawers for pans and heavy stuff. This means getting really good heavy duty rollers. We are going to make the bottom left corner a wine rack with a glass front. The three doors on the upper shelves will all lift upwards. When I order the heavy duty drawer sliders I will order good hinges. We are going to use the same knobs and pulls we are going to install in the repainted kitchen cupboards. I will need to get that order in soon also.

I had a chicken die last week and Annmarie made me promise to call the state if another one died. I had to call and talk to several people before they left a message for the state vet. He called the other day and we discussed my dead chicken. Our chickens have no direct contact with any waterfowl. All confirmed cases of H1N1 in domestic birds have been from direct contact with waterfowl feces. So not the cause of my bird death most likely. If I continue to have unaccountable deaths I need to freeze the chicken and contact them again. He was very helpful and answered all my questions. A most pleasant interaction.